What does the provide

Suppose you plan to start this aluminum radiator project. In that case, we are an excellent radiator machine manufacturer and supplier that can provide one-stop services for mechanical equipment and complete technical training services.

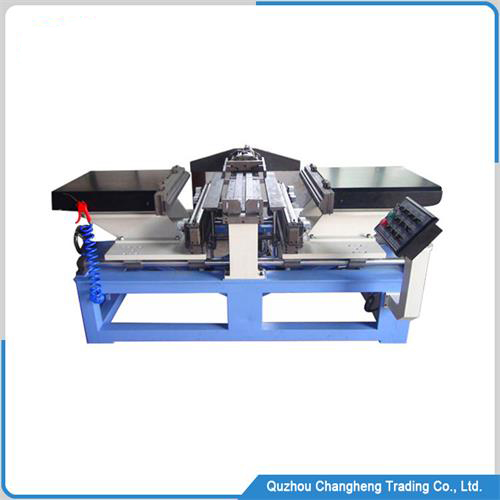

Manufacturing car engine radiators requires many machines in current industrial production, each completing their respective tasks. For example, manufacturing cooling fins requires specialized fin-making machines, and welding cores require aluminum brazing furnaces,

A factory that produces high-quality aluminum radiators not only requires suitable machines but also mature technology, which poses some difficulties for a new factory to master proficient technology,

Radiator machine manufacturer available for selection

Radiator machine manufacturer services

- Full technical support:

We provide you with technical support throughout the entire process from project initiation to production operation, ensuring that any technical issues you encounter during installation, debugging, and daily production are promptly and effectively resolved.

- One-stop machine procurement:

We can provide a complete set of production line equipment according to your needs, including but not limited to fin manufacturing equipment, radiator brazing equipment, and aluminum core assembly equipment, so that you do not need to purchase from multiple suppliers separately, simplifying the procurement process.

- Regular maintenance and repair:

To ensure that your equipment is always in optimal working condition, we provide regular maintenance and quick response repair services in case of equipment failure, reducing the risk of production interruption.

- Radiator parts supply:

Radiator machine manufacturers also provide supply services for radiator components to ensure that any replacement parts or accessories you need during the production process can be obtained promptly, ensuring the continuous operation of the production line.

wechat

wechat