Machine Overview

What radiator making machine are needed by factories producing aluminum radiators? Some people plan to start a factory producing aluminum radiators, but they don’t know which machines are needed and how to start this work. These issues have troubled many people,

We have 19 years of experience in producing aluminum radiators. Today, I would like to clarify which machines are essential for an aluminum radiator factory; This is the smallest unit of an aluminum radiator factory; we hope to help some new ones.

Radiator making machine list

Machine Details

brazing furnace

The machine is the most critical part of the aluminum radiator production process. When the aluminum core is assembled and needs to be brazed, all core parts are welded together.

Please check this video to understand the production process of the brazing furnace.

For more details about brazing furnaces, please click here

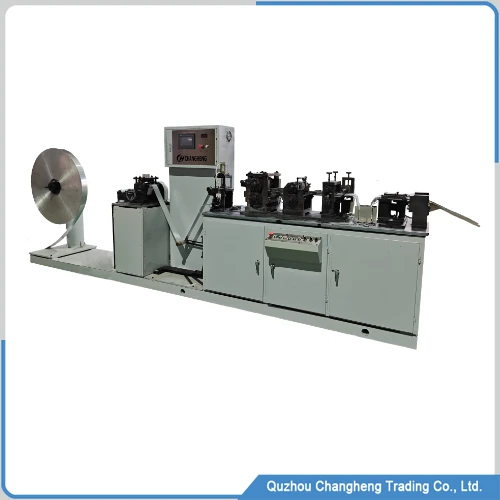

Fin machine

This radiator fin machine is very important in the production process of aluminum radiators. Its function is to produce aluminum fins. A roller produces this machine, so its work efficiency is very high. Some large aluminum radiator factories usually have multiple fin machines.

Please check this video to understand the production process of the Fin machine.

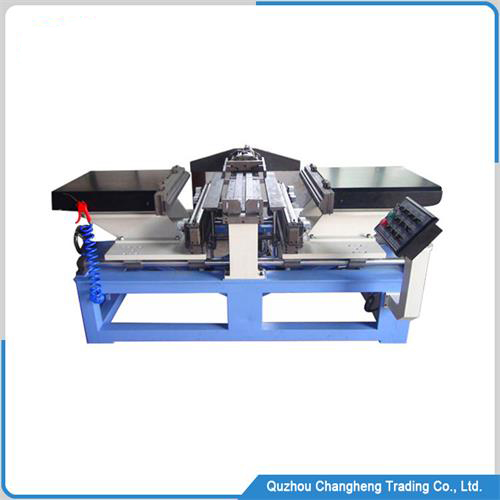

Core assembly machine

This type of core assembly machine must be present; It is a common equipment for producing aluminum radiators

With the development of industry, many automatic production machines are currently costly. Generally, factories that produce aftermarket radiators do not use expensive machines. Today,

I recommend the core manufacturing machine as the most practical equipment. It has many characteristics, such as low price, fast production speed, and low power consumption.

Plastic tank crimping machine

The application of this machine is to assemble plastic tanks, aluminum cores, and sealing gaskets together, and It is the essential equipment of the radiator-making machine.

Some small-scale aluminum radiator factories use semi-automatic machines, which are cost-effective.

Some large factories use automatic machines, which can achieve automatic avoidance functions by preset machine work steps.

There are many different types of crimping machines on the market.

Leak testing machine

This machine is mainly used to test the leakage of aluminum radiators and is also an essential part of radiator-making machines.

It has two workstations, which means it can test two heat sinks simultaneously, greatly improving work efficiency.

There are also many types of machines to choose from; as mentioned earlier, I only recommend the most practical equipment.

Another radiator making machine

Liquid nitrogen storage tank

This equipment is designed for aluminum brazing furnaces, as nitrogen gas is required throughout the entire aluminum brazing process

air compressor

The new aluminum radiator factory requires almost all equipment to provide compressed air support. Otherwise, these machines will not work properly

Radiator-making machine working video.

This factory is located near Shanghai, China. The straight-line distance from Shanghai to the factory is about 300km. The factory can produce 30000 aluminum radiators for passenger cars every month. This scale of factory is relatively small in China

Next, please enjoy a complete video of an aluminum radiator factory

How to choose radiator making machine

1, Production demand: Clearly define your production scale, expected output, and types of products to be produced. This will help determine the type, size, and production capacity of the required machines.

2, Machine accuracy: The dimensional accuracy of radiator components directly affects product quality. Choosing a machine with high accuracy and good stability is crucial.

3, Automation level: Consider introducing machines with higher levels of automation to improve production efficiency, reduce labor costs, and enhance product quality consistency.

4, Compatibility: Ensure that the selected machine is compatible with other devices to build a smooth production line.

5, Maintenance and support: To reduce long-term operating costs, choose a radiator-making machine that is easy to maintain and has good technical support from the manufacturer.

6, Training and service: Confirm whether the supplier provides operational training and technical support, which is crucial for the smooth deployment of new equipment.

7, Budget and cost-benefit analysis: Compare the prices and performance of different machines, conduct a cost-benefit analysis, and select cost-effective equipment.

8, Energy efficiency: Consider the energy consumption of radiator-making machines and choose machines with high energy efficiency to reduce operating costs.

9, Safety performance: Ensure that the selected machine complies with local safety standards and regulations, ensuring the safety of operators.

wechat

wechat