Product Introduction

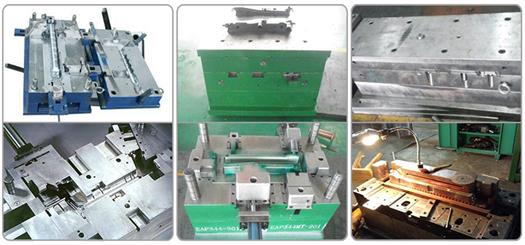

The radiator plastic tank mold is a kind of industrial production mold. It is precisely designed, and the internal mold cavity is made using modern industrial manufacturing techniques.

The mold consists of parts such as the mold cavity, slider, ejector pin, and stripper plate. The material of the mold cavity is DCI4050, which has excellent wear resistance and can extend the lifespan of the mold.

Since the material of the radiator tank is PA66-GF30, higher requirements are placed on the quality of the mold. Therefore, the mold must be designed with a hot runner so that the mold can always maintain the set temperature and improve the quality of the product.

Radiator plastic tank mold Technical Parameters

- Place of Origin: China, Zhejiang, China

- Model Number: OEM

- Shaping Mode: Plastic Injection Mould

- Product Material: Plastic

- Material: PA66-GF30

- Color: Black

- Product Type: plastic brush injection mold/brush case plastic molding making

- Surface treatment: Mirror Polish

- Plastic material:ABS/PP/PS/PE/PVC/PA6/PA66

- Size: Standard Customize

Why choose us

- Experience with paper dispenser mold

- Free 3D Drawing service from plastic to plastic injection molding tool design

- 2 exceptional after-sales teams to help you solve any problem with plastic injection mold tooling and parts.

- We are ready to sign a contract with you in case you need to ensure the quality OR delivery date of our plastic molding tooling and plastic parts.

- Time is gold for you and for us. We have a professional plastic injection mold tooling designer and plastic part-producing line.

- Plastic Injection Mould OEM & ODM Services

- ISO9001 and ISO 14001 Certified for all of our plastic injection tooling and plastic mold part, injection mold, and our factory

wechat

wechat