Equipment usage

The Tank Clinching Machine actively assembles aluminum radiators designed for truck engines. It combines the radiator core, a sealing gasket, and plastic tanks, securely forming a closed container.

This active process highlights the machine’s role in constructing a robust, leak-proof radiator system essential for efficient engine cooling in trucks.

Tank Clinching Machine Main Features

This device uses a well-known brand of touch screen and PLC system to control the device. It may allow workers to set unique programs for each heat sink model, and this machine can store 999 data parameters

This machine only requires a simple setup work program, without additional mold costs, It can produce radiators of various sizes

This device uses a well-known brand of servo motor to drive the ball screw, making it step along a linear guide rail. This equipment is divided into long-edge buckle presses and short-edge buckle presses.

it can avoid and move forward according to the shape of the water chamber of the workpiece

Technical parameters

| ITEM | DATA |

| max size | 1000*8500mm |

| max thickness | 150-280mm |

| Production speed | 80/h |

| Machine weight | 1.8T |

| power supply | AC-220V/50Hz |

| Voltage level | 2.5kw |

| Equipment size | 190*185*210cm |

Radiator Tank Clinching Machine working video

Customer Service

If you are looking for a plastic tank Clinching Machine, our machine is the right choice for you. It can not only produce car radiators but is also be compatible with truck radiators

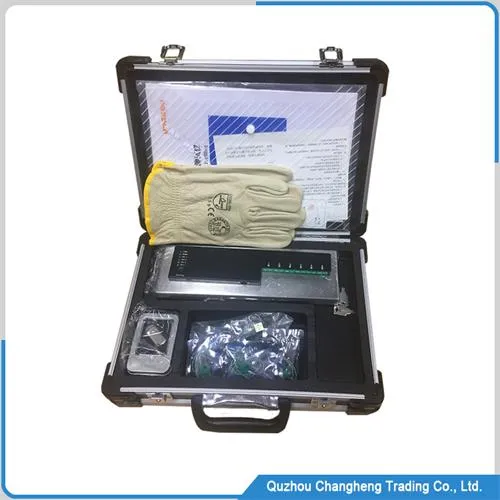

We provide sea freight, machine installation, and technical training services. We also prepare some easily damaged parts for the machines and package them for 3-5 years of use in your factory.

For more services, you can contact our engineers, who will answer all your concerns

wechat

wechat