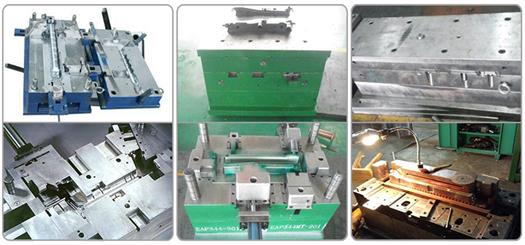

Mold Overview

This plastic injection mold for car radiators has a hot runner control and water cooling device inside. It can be installed on any brand of horizontal injection machine for use,

We specialize in designing and manufacturing plastic water tank injection molds for automotive radiators, covering all aluminum radiator models in the aftermarket. With 19 years of work experience in this field, we can perfectly manufacture any plastic tank you have.

We can provide satisfactory solutions whether you need high-quality molds to produce OEM radiators or ordinary-quality radiators for the aftermarket.

Plastic Injection mold material

- Chamber: P20

- Top pin: NAK80

- Sliding block: Cr12MoV

- Spring: 50CrVA,

- Base plate: EN C45,

- Injection port: 4Cr13MoV

- Mold frame: EN C45

Plastic Injection mold data

| ITEM | DATA |

| Place of Origin | Zhejiang, China |

| Brand Name | CHANGHENG |

| Product Material | PA66-GF30 |

| Mold color | Any color |

| Cavity | 1-4 unit |

| Surface treatment | Mirror Polish |

| Application | Car radiator |

How to make plastic injection molds

Manufacturing a plastic mold is very complex, but each mold has the same production process.

- Manufacturing task input

The manufacturer receives the customer’s design or sample, and both parties reach a consensus,

- Design molds

Manufacturers design the overall structure of molds based on the particular characteristics of plastic samples and then draw 3D models for CNC machining.

- Purchase raw materials

Every plastic injection mold part required to purchase raw materials and manufacture molds must have a tolerance that meets the design standards.

- Assembled plastic injection molds.

Assembling the mold is a crucial step, and the slider and ejector pin must move flexibly without interference from each component.

- Test the mold

When the mold assembly is completed, it needs to be installed with an injection molding machine for final testing to ensure that the quality and size of the produced product meet the design requirements.

- Improvement and optimization

If some defects are found during mold testing, the manufacturer needs to improve and optimize it.

- Deliver to the customer.

Optimize the plastic Injection mold’s appearance, package it, and deliver it to the customer for use. At this point, the entire mold is manufactured.

What are our advantages?

1, We focus on automotive radiators, and our reliable quality wins the trust of our customers.

2, Our engineers have extensive work experience; no matter how complex your radiator tank is, we can provide high-quality molds.

3, Our costs are very competitive due to our focus on large-scale production of plastic molds for automotive radiators.

4, Plastic mold factories are located in cities with developed industries. If you urgently need molds, we are confident we can deliver them quickly.

Q & A

A: Our mold delivery time is usually 45 working days; in exceptional cases, it may be 55.

A: Usually, our plastic Injection molds are packed in wooden cases.

A: Our engineers can use CAD, Solidworks, Catia, Inventor, Pro/ENGINEER, ug

A: The service life of our mold is 300000 times

wechat

wechat