Mold Outline

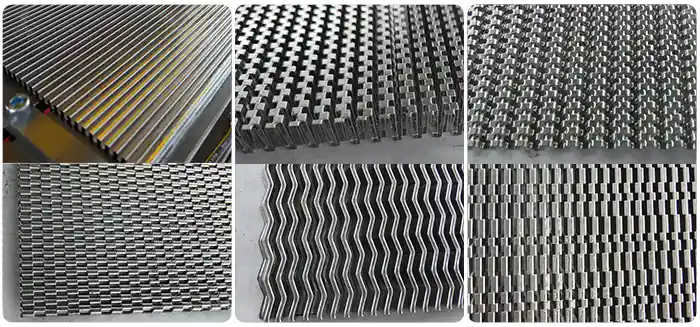

The sawtooth fin mold of the industrial cooler heat exchanger, which is a customized mold, mainly produces sawtooth-type fins. The mold design is reasonable and the service life is long

The serrated fin die is an essential industrial mold for the production of heat exchangers, It is mainly suitable for the continuous production of fin machines. Changing a mold can achieve the production of different types of fins to meet the needs of different customers

Compared to our competitors, our molds have 8 customized springs, and each mold has 6 guide pillars. Our molds produce fins with more stable quality and longer service life

The maximum height dimension of this mold is 12mm. By adjusting the machine, this fin tool can produce a height dimension of 0.5-12mm. This is currently the best solution in the industrial field, saving our customers a lot of money

Die application: it is used in cooling system parts, copper, aluminum, iron, and other materials

Mold features: small size, fast stamping speed, high positioning accuracy, low price

Mold requirements: customized according to customer requirements

Types of fin molds

| Forming mold | Industry fin die |

| Punching die | heat exchanger fin die |

| Cutting die | sawtooth fin die |

| fin Serrated mold | Straight fin die |

| Louver fin stamping mold | Wave fin die |

Our processing equipment

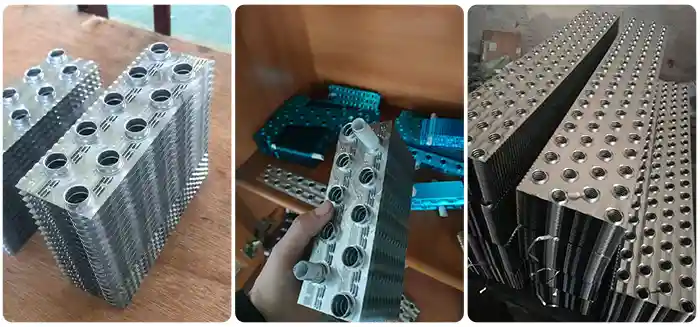

Fin mold of heat exchanger

This is a specialized fin die for producing cold air fans, condensers, evaporators, and radiators. This fin die is designed according to the special requirements of different industries, such as elliptical fins, oblique cut fins, punched copper fins, or steel fins, etc.

With the development of industry and people’s continuous pursuit of production speed, the maximum production speed of this mold to meet market demand is 250-300 times per minute

To meet the requirements of each customer, fin press molds can produce various types of raw materials, such as aluminum, copper, stainless steel, titanium alloy, iron, etc

| ITEM | DATA |

| FIN PATTERN | CORRUGATED |

| ROW | 4-16 |

| FIN TYPE | RIPPLE |

| TUBE SPACING | 38.1mm |

| FIN PATTERN | 1.5”*1.5” |

| TUBE | 5/8” |

| ROW SPACING | 33mm |

wechat

wechat