Product Description

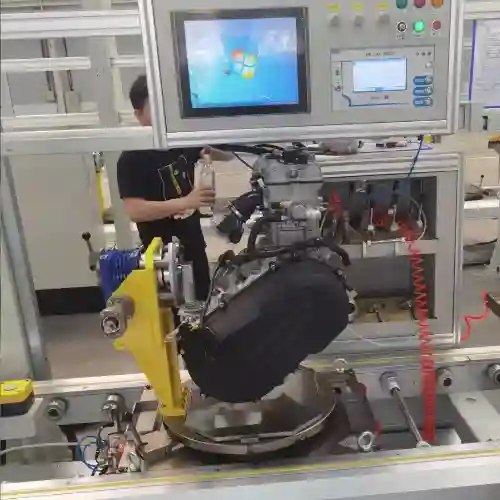

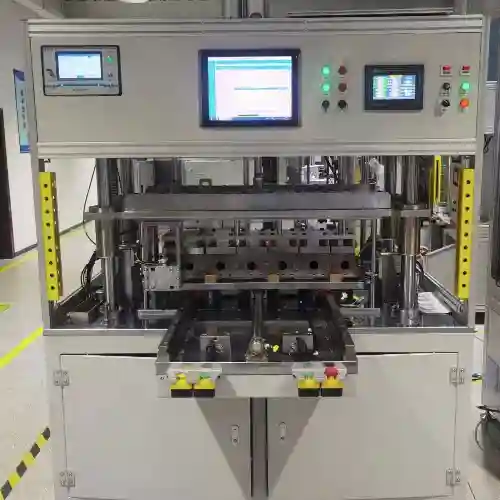

The seal test machine is industrial production equipment. It injects compressed air into the interior of parts and maintains a specific time to determine whether the parts have any leaks.

The equipment comprises a sealing test device, a workbench, automated tools, and more. It can quickly replace different tools to test different functional parts and switch test modes under any working conditions.

To ensure the accuracy and stability of the test process, the test pressure and sealing time can be set according to different product characteristics.

Technical Parameters of Seal Test Machine

| ITEM | DADA |

| Power source | Single phase 220V |

| Voltage | 24V |

| Workbench size | 150*100cm |

| Test pressure | 0.4-0.6mpa |

| Testing tool: | Customize |

| Test time | 0-999 seconds |

| Resolution | 1-10 pa |

| Machine brand | CHANGHENG |

| Vacuum test | Optional |

| Appearance color | Gray-white |

| Frame | Aluminum alloy |

Seal test machine advantage

1. This machine can test various industrial parts, such as household products, automotive, electrical, and aviation parts.

2. The flexible workbench design allows for low-cost tool switching and testing of more parts. Combined with automated tools, it can fully automate part testing.

3. The workbench’s frame is made of aluminum alloy, and the desktop is SS304. The parts for fixing sheet metal come from high-quality blind rivet manufacturers in China. They are installed firmly and have a beautiful appearance. This kind of workbench seems to be an industrial art piece.

4. This sealing test machine reserves multiple IO output interfaces, and users can connect external devices to share data and implement Industry 4.0.

5. Touch screens visualize parameter settings and human-computer interaction, allowing workers to master their operation logic quickly and reducing the cumbersome training process.

6. The parts used for testing pressure are highly precise and come from internationally renowned brands. They can accurately detect even the slightest leaks.

Our Support and Services

Customization services for tools.

Our Seal Test Machine can test many industrial parts. Our team of engineers can design customized testing solutions based on the special characteristics of our customers’ products.

Whether you want to automate testing production on a large scale or conduct high-precision experimental validation, we can design and manufacture dedicated tools for your product.

Warranty Policy

The warranty period for this machine is 12 months. During this period, if there are any problems with the equipment, we will provide free repair services.

In the future, if any parts of the machine wear out, we will also provide free parts support to ensure that users can use this machine smoothly for 3-5 years.

Ocean transport services

This Seal Test Machine is packaged in a wooden box, and the wood meets international logistics standards. We will deliver it to your factory on time, no matter which country it is in.

Technical training services

The operation logic of this machine is very simple, with visual input parameters. Our manual can help you operate it easily.

We can offer this service if you want our engineers to provide on-site training.

Seal test machine Application scenarios

The machine uses compressed air and high-precision sensors for testing, and the test results are presented visually on the screen.

Thanks to its high sensitivity detection and remote operation and management support, this machine has a wide range of applications in producing products in the industrial field.

Here are some examples of application scenarios.

1. Automotive field: For example, engine radiators, air conditioner condensers, engine housings, oil filters, gasoline tanks, and car headlight parts. These parts need our machine seal test.

2, Home appliances: water heaters, washing machine motors, heating heat exchangers, air conditioner condensers, sinks, and other products and parts.

3, Laboratory: In some R&D fields, many experiments need this machine to conduct sealing performance tests on some special products or parts.

4, Agricultural field: Water conservation and irrigation, pest control spraying, and the constant temperature system in greenhouses. The products in these fields must be tested for sealing to ensure reliability.

wechat

wechat