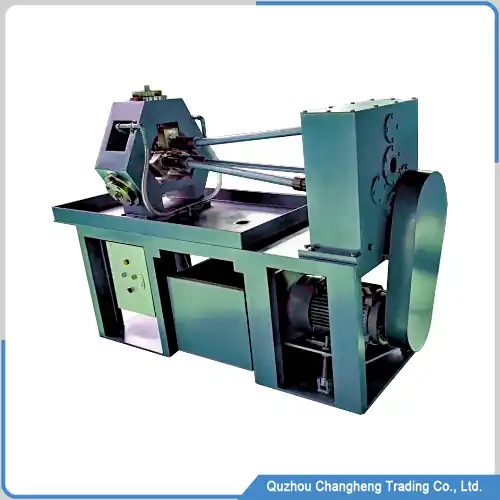

Product Description

The radiator tank clinching machine primarily creates radiators for automobiles. Some claim that it’s a semi-automatic crimping machine. An air cylinder serves as the major power source. The production pace is excellent. Two operating modes exist. The machine is run by one factory, or two workers can run it concurrently.

Advantages of the radiator tank clinching machine

1. The machine has simplified, redundant designs, keeping only the key parts and important structures, so it is very cost-effective.

2. Due to its simple structural design, its maintenance and repair costs can be ignored during long-term use.

3. The machine does not have a complex control system, and it adopts a semi-automatic working mode in the production process. Therefore, workers do not need to undergo complex training and can easily use the machine. This is very helpful for factories where worker turnover is very frequent.

4. Without a motor and other mechanical movements, this semi-automatic clinching machine won’t produce any noise during work.

5. This machine uses compressed air to drive the cylinder, so it has no additional power consumption. Its power consumption per hour is about 24w, which is very energy-efficient.

Product quick details

- Working mode: semi-automatic

- Operator: Single person

- Setting up work steps: No need

- Maximum length: 800mm

- Maximum height: 800mm

- Header plate width: 150mm

- Driving mode: pneumatic

- Voltage: 24v

- Machine color: Gray-white

- Radiator Type: Truck, Car, Bus

- Delivery time: 35-40 days

- Repair time: 12 months

Plastic tank clinching machine working video

Q & A

A: This machine will deliver in 45 days.

A: We can produce 80% of the aluminum radiators in the aftermarket.

A: We accept 100% irrevocable letters of credit, of course.

A: This machine’s workspace measures 800 by 800mm. This range of radiators can be created. To generate huge radiators, increase the size of their working area. To have the machine customized, speak with our engineers.

Automatic radiator tank clinching machine

An automatic machine is suitable for large-scale production in aluminum radiator factories. It can press all four sides of the radiator at once, which significantly improves production efficiency.

This automatic production machine uses servo motors to control the operating steps, and pneumatic cylinders are responsible for pressing the aluminum header plate. The machine needs to set an independent working step for each type, such as the radiator.

You can check out the video below to learn more about the details of the automatic pressing machine.

wechat

wechat