summarize

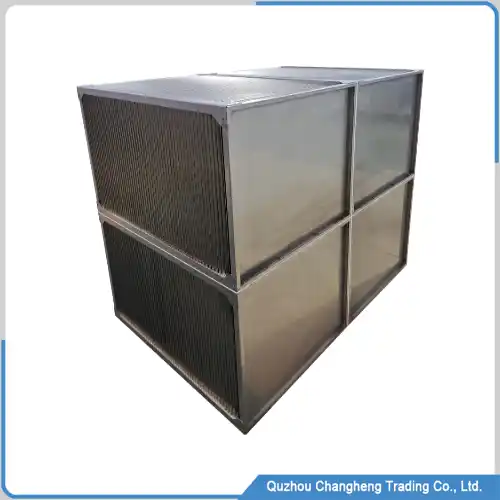

A sensible heat exchanger is a device used for transferring air heat energy conversion, which achieves heat transfer through the temperature difference between air. With people’s yearning for a better life and awareness of energy conservation and environmental protection, many residential buildings now install air-to-air heat exchangers

There are various types of sensible heat exchangers, including plate heat exchangers, shell and tube heat exchangers, spiral heat exchangers, etc. Each type of heat exchanger has its specific application scenarios and advantages and disadvantages. This article mainly discusses the production of sensible heat exchangers

Sensible heat exchanger production line

This is a new product, and some new factories do not have a good production solution. Usually, ordinary stamping machines and robotic arms are used to produce the plates of heat exchangers. This production method itself is a serious waste, with slow production speed, inability to ensure product consistency and very expensive production costs

The production line we provide is professional equipment designed specifically for sensible heat exchangers. The machine has a simple structural design, with a maximum production speed of 10-20 pieces per minute. The production line is hydraulically driven, and there is no noise during the production process

Advantages of the production line

- Multi-size sharing

After reasonable layout design, a mold can produce various sizes of plates, such as 500*500mm, 600*600mm, 850*850mm, and 1000*1000mm

- Unmanned and fully automated production

This Sensible heat exchanger production line can achieve fully automatic production, and the machine will automatically stop when the output reaches the set value

- High-quality electrical control components

The control components of this equipment are all from internationally renowned brands such as Mitsubishi, Siemens, Delta, etc

- Efficient servo motor drive

In the automatic production process, the movement of aluminum foil is driven by a servo motor, which can accurately control the distance of each movement and effectively ensure product consistency

- The height of the aluminum plate is adjustable

The pressure mold has been scientifically designed, and the height of the convex hull can be freely adjusted to achieve different plate distances and meet the heat transfer efficiency requirements of different customers

Sensible heat exchanger production line data

| ITEM | DATA |

| Touch screen: | Delta |

| PLC brand: | Mitsubishi |

| Mold size: | 200-1200mm optional |

| Drive type: | hydraulic servo |

| External dimensions: | 600*120*160cm |

| Color: | Any choice |

| Delivery time: | 65 days |

| Plate material: | aluminum copper stainless steel |

Sensible heat exchanger Production process

1, Place the raw materials on the uncoiler equipment of the machine and fix it in place

2, Place the aluminum foil on the equipment, and the production line will know its operation. The production process of the plates is fully automated

3, After the aluminum plate is pressed into shape, the workers need to bend the four sides of the edges, and our production already includes this bending tool

4, The bent aluminum plate is manually folded to form a complete aluminum core, which requires manual labor to complete

5, Install fixed brackets on the completed aluminum core to form a complete sensible heat exchanger core

wechat

wechat