Machine Overview

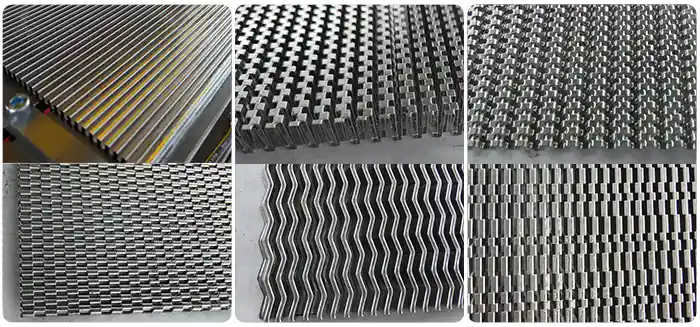

The stainless steel fin machine is a highly automated equipment that can produce various types of high-precision fins, such as serrated and wavy types.

This type of machine is usually equipped with a PLC touchscreen control system to achieve visual operation, allowing operators to intuitively understand the operation status and production process of the equipment.

Stainless steel fin machine Features

1, High precision:

This fin machine can produce high-precision fins, ensuring that the quality and performance of the product meet the standards.

2, Stable operation:

The machine adopts a four-pillar design, which has stable operating performance and can run continuously for a long time without any faults.

3, Quick mold replacement:

The mold replacement speed of this Stainless steel fin machine is fast, producing various types of fins to meet different application needs

4, Strong scalability:

This machine has good scalability and can be connected to other automated production lines to achieve automated production.

5, Simple operation:

The machine is easy to operate, learn, and master, reducing the difficulty of operation and training costs.

Technical Parameter

| No. | ITEM | DATA |

| 1 | Fin material | stainless steel |

| 2 | Lubricating oil | volatile oil |

| 3 | Fin type | serrated wavy straight |

| 4 | Fin height | 1.5-12mm |

| 5 | Maximum width | 300mm |

| 6 | Cutting type | automatic |

| 7 | MOQ | 1 pcs |

| 8 | Delivery time | 45 days |

Stainless steel fin machine working video

Working principle

1, Unwinding machine:

It is used to fix and unfold metal coils, and smoothly feed materials into subsequent processing equipment.

2, Lubrication device:

Before the metal sheet is pressed into fins through a mold, a layer of lubricant is usually applied to the surface of the sheet to protect the metal surface from damage.

3, Fin press machine:

It uses molds to press metal materials, forming specific geometric shapes such as serrated or wavy shapes

4, Cutting device:

After the fins are pressed out, they can be accurately separated according to the predetermined size.

This is the entire production process of the stainless steel fin machine, and the equipment can achieve unmanned production throughout the entire production process

wechat

wechat