Product Description

A Temperature thermal profiling records the working time and temperature of heat treatment.

It collects temperature data through a thermocouple and transmits it to a computer to form a curve. Engineers can refer to these temperature data to continuously improve the quality of the product.

This instrument is needed in most heat treatment industries, where temperature data is collected and analyzed, such as large food-cooking factories, metal heat treatment, high-temperature brazing, and paint drying rooms.

This temperature profiler uses the latest WiFi transmission technology, allowing users to view temperature changes online through a computer. This technological innovation has important practical applications.

Working Principle of Temperature Thermal Profiling

Record temperature data is a complex process, and it will be more difficult if we record different temperature data in multiple locations. However, using thermal analysis makes this process relatively simple.

It can not only record the temperature distribution over time but also use multiple thermocouple probes to monitor temperature changes in different locations. These data are very helpful for improving product quality and continuous improvements.

The new temperature profiler uses WIFI transmission technology. You can check temperature changes online by connecting to a laptop’s WIFI hotspot. In case of an emergency, engineers can respond quickly and solve these problems.

Thermal Profiling working video

Software of Thermal Profiling

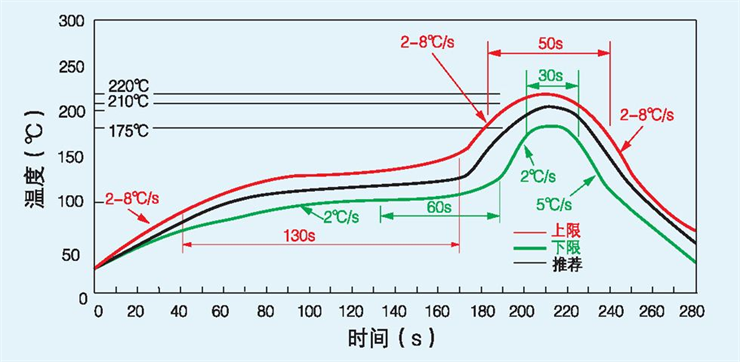

This software runs on Windows-based computers or tablets. It offers various language options, including Chinese and English.

It automatically generates a temperature distribution report, with the horizontal axis representing time and the vertical axis representing all temperature changes. The temperature and time form a curve displayed in the document, which engineers can analyze and record.

The software has multiple preset report templates, allowing engineers to print temperature data reports conveniently and quickly.

Engineers can also customize design reports and save them as templates. This flexible design helps to improve the efficiency of engineers’ work.

Technical Parameter of Thermal Profiling

| ITEM | DATA |

| Data storage | 16 sets |

| Features | WIFI transmission |

| Channel | 4-10 optional |

| Battery | Rechargeable |

| Probe | K thermocouple |

| Resolution | 0.1 ℃ |

| Maximum temperature | 1250 ℃ |

| Software | Windows 11 |

Matters needing attention

Some special equipment requires instruments to enter the device’s interior to collect temperature data, and then the insulated box plays its role.

We designed a heat insulation box for the temperature Thermal Profiling and customized it according to the size of the special equipment.

Please note that when you test the temperature data once, the thermal profile needs to leave the incubator immediately, wait for the incubator to cool down completely, and then use it again next time.

The profiling will likely burn out if the incubator is not thoroughly cooling.

Thermal insulation box design

This insulated box is made of SS316L, which is highly heat resistant. It will not deform at a temperature of 1350℃.

The inside is filled with the best heat insulation material. It is then wrapped in high-temperature cloth and pressed and molded with a hydraulic press.

The heat insulation box has two parts: the bottom and the lid. In the middle is space for the heat absorption box and the Thermal Profiling

The heat-absorbing box is a crucial part of our core technology. The temperature entering the heat insulation box is all absorbed by it, protecting the instrument from malfunctioning.

Support and Services

1. We can customize insulated boxes according to our customer’s application needs and provide the best solutions regardless of which industry you are in.

2. This profiler is guaranteed for lifetime maintenance. We offer comprehensive repair services for any problems you encounter with your instrument.

3. We have had a large inventory for a long time. When you place an order, we will respond quickly, and you can receive this Thermal Profiling without waiting.

4. Software update service. As the system is updated, our software will also be updated. In the future, you can get the latest software support anytime.

5. Technical support. Our engineers are very professional in many heat treatment industries, and we can provide good technical support.

wechat

wechat