Machine Overview

Finning machines produce metal fin tubes. Their primary function is forming an aluminum fin structure on metal tubes, typically used in radiators, heat exchangers, and industrial equipment. Small fin tubes are also used in household appliances and the sanitary ware industry.

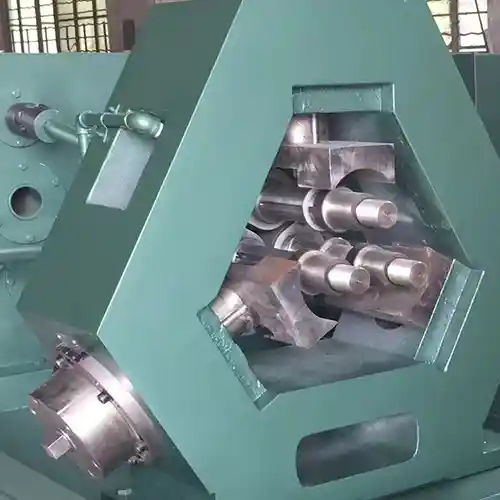

The tube fin machine’s structure consists of three rotating main shafts and a fixed base. Each main shaft has a roller knife, and the motor drives the gearbox, which transmits power to each main shaft through a belt. The roller blade squeezes and cuts the outer tube to shape the fin.

This machine is highly efficient and cost-effective, making it very popular.

Finning machine advantages

1, High production efficiency: This machine can produce many pipes quickly, improving production efficiency.

2, High production accuracy: The accuracy and quality of the pipes can be guaranteed through precise processing to form a fin-like structure.

3, Customizable: This finning machine can be customized according to customer needs to produce exceptional performance and structure pipes.

4, Low production cost: A set of roller molds can produce various fin tubes of different diameters without the need for additional mold investment

5, Environmental protection: The production process of the Fin Machine does not generate waste, so it will not cause any pollution to the environment.

Finning tube parameters

| Item | Data |

| Outside Fin material | Copper Aluminum |

| Tube material | Copper Carbon steel SS304 Aluminum Alloy |

| Fin thickness | 0.1-0.4mm |

| Tube diameter size | 10-38mm 8-51mm |

| Fin height | < 17mm |

| Fin pitch | 0.6-2mm 1.6-10mm |

| Tube diameter | Φ25-88mm |

| Tube length | < 20m |

Finning machine parameters

| ITEM | DATA |

| Machine colour | Green |

| Packaging size | 145*75*150cm |

| Roller blades | 3 sets |

| Packaging | Wooden box |

| Motor power | 11 & 22kw |

| Certificate | CE |

| Delivery time | 42 days |

Tube finning machine working video

Application scenarios

This machine can produce metal fin tubes of different diameters used in various industrial fields, such as the shipbuilding industry, greenhouse heating, solar power plants, petroleum refining factories, etc.

With industry development and technological innovation, more and more household appliances and bathroom furniture industries are also using this fin tube. Due to its intense heat dissipation capacity and easy bending and deformation characteristics, this tube will be used by more industries in the future.

Q & A

A: Our machines are in stock. The delivery time for the tube finning machine is 25-32 days.

A: Our machine is from China’s top tube finning machine manufacturer.

A: The machine’s default color is green, but we can also spray it in your preferred color.

wechat

wechat