Machine Overview

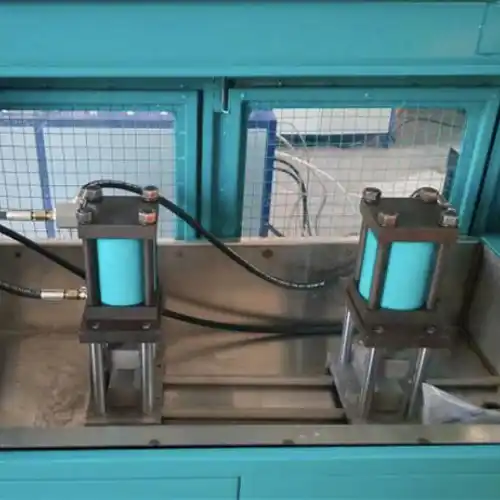

This tube testing machine is an aluminum alloy tube pressure burst testing equipment with two pneumatic boosting devices and a maximum output pressure of up to 80mpa. Engineers can freely control the testing pressure to test different tubes and tasks

This device’s appearance is made of a 1.5mm metal plate bent by CNC, and the color of the appearance can be customized.

The booster pump and electronic control part are installe inside to reduce the space occupied by the equipment,

Main technical parameters

| ITEM | DATA |

| Tube wall thickness | 0.2-2.0 mm |

| Short axis | 1.3-3mm |

| Burst pressure | 50 MPa |

| Measurement accuracy | ≤ ± 0.5%FS |

| Ambient temperature | room temperature |

| Work Medium | water emulsion hydraulic oil |

| maximum Length | 800mm |

| Control mode | automatic control manual control (optional) |

Working principle of Tube testing machine

The test tube testing machine uses compressed air as a power source. The booster pump increases the gas pressure to a greater extent; the pressure regulating device controls the pressure and outputs it to the testing tool.

The testing tool compresses both ends of the aluminum tube, transmits pressure to the inside of the tube, and then increases the pressure and maintains it for a particular time,

Then, check the expansion changes or bursting of the aluminum tube to determine its quality,

During the testing process, the computer records changes in pressure and time and automatically produces visual file reports.

Aluminum tube testing machine Characteristics

1. This equipment is used for blasting tests and testing the maximum pressure metal pipes can withstand, with a maximum pressure of 80mpa. Users can set different pressures for testing using different metal materials.

2. This tube test machine uses a pneumatic booster to test the stable pressure output and applies hydraulic pressure to tighten the sample to ensure air tightness.

3. Metal pipes connect the pressure transmission inside the equipment, and the structural design is reasonable. The device has a small volume, lightweight, and has a beautiful appearance

4. During the experiment, the pressure is automatically compensate. The pressure drops rapidly after the metal pipe breaks, and the system stops pressurizing.

5. Realize computer control function, freely set water filling, exhaust time, pressure holding time, inflation, cleaning time, test pressure, and all technical data can be freely controlle.

Tube testing machine control system

The control system is an industrial computer installe on a workbench and equipped with an Electric Transfer Chair, allowing engineers to sit here and focus more on their work,

The sensors of the aluminum tube testing machine convert data into numbers and transmit them to the computer through data cables for practical technical analysis,

The analysis software has multiple built-in file templates, enabling engineers to print test reports quickly.

Application of machine

In the industrial production process, some products need to check the quality of the pipes, so this pipe testing machine plays a role. It tests the ultimate pressure-bearing capacity of metal pipes and records accurate data. Engineers can use this data to improve product design and meet customer quality requirements,

So this machine is needed in many fields. Let’s tell you a few typical cases.

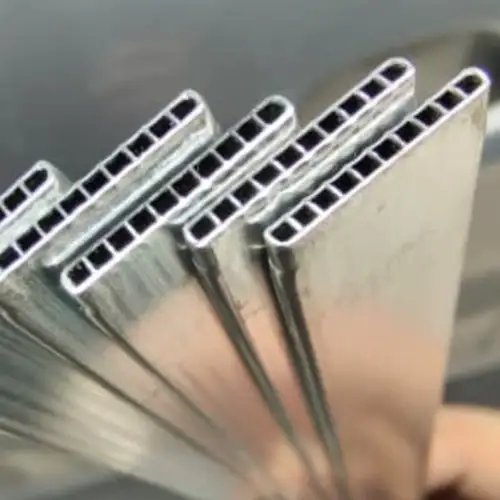

1. Automotive aluminum radiator, which is a critical component, requires pressure testing during the production process to ensure quality stability

2. Condenser microchannel aluminum tube, which is an extruded aluminum tube, the uniformity of temperature will affect the tube quality, so it is necessary to verify the quality of the tube testing machine.

wechat

wechat