Product Introduction

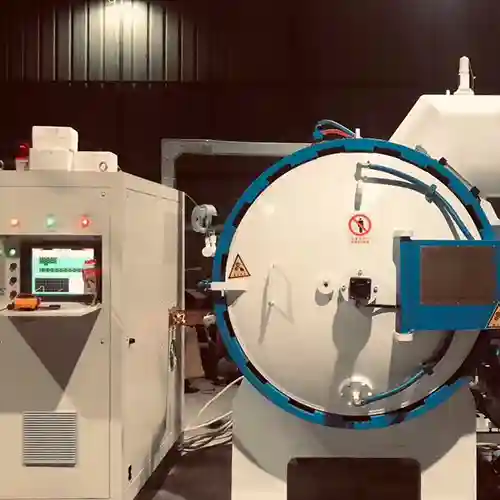

The vacuum aluminum brazing furnace is a high-end equipment that provides one-time welding for complex aluminum products. When ordinary welding processes cannot meet production needs, this vacuum brazing technology plays its role and perfectly solves this complex welding problem.

In the production process of aluminum products, complex parts are usually assembled into a whole,

then fixed with special metal tools and placed in a vacuum furnace for high-temperature vacuum brazing. This process is usually controlled automatically.

What are the parts of the vacuum aluminum brazing furnace

Furnace body

This is the location where aluminum products are uses for welding production. The furnace body comprises multiple layers of metal welded together, with a middle layer containing pipes for circulating cooling water. There are heating devices and nitrogen pipelines inside, and an independent furnace door,

The internal dimensions of the furnace body are manufactured based on the maximum size of the user’s parts, and the larger the size, the more expensive its manufacturing cost will be,

Vacuum pump

There are many types of vacuum pumps, such as Roots, diffusion, slide valves, maintenance, etc. Each pump has a different function and plays a vital role in the efficient operation of brazing vacuum furnaces,

The vacuum pumping pipeline includes a baffle valve and a differential pressure valve. Together with the vacuum pump, they form a complete vacuum system that meets the vacuum pressure requirements of aluminum brazing.

Electric heating

Due to the particularity of the aluminum vacuum brazing furnace, all 5-6 surfaces of the workspace need to be heat and maintain good temperature uniformity,

Therefore, the vacuum furnace will have an independent transformer for precise control of the heating device, ensuring the smooth operation of the vacuum furnace.

Control device

The efficient operation of a vacuum furnace requires a complex control system to regulate the changes in its vacuum pressure and temperature.

Our vacuum furnace has a PLC and industrial computer to control, which programs complex operations and intelligently controls the workflow.

Water-cooling

The water cooling device is installed in the middle of the furnace body’s interlayer, and the pipes are regularly distributed at various positions of the furnace body to cool the entire furnace body evenly.

When the vacuum furnace is running, the cold water also automatically starts working, keeping the surface of the furnace body at a lower temperature and providing a comfortable temperature for the entire workshop.

Nitrogen protection

Nitrogen is an emergency protective measure. In some countries, electricity is unstable, and when the vacuum furnace experiences a sudden power outage during high-pressure welding, the vacuum pressure will disappear,

At this point, nitrogen protects aluminum materials from oxidation and deterioration caused by vacuum deficiency.

Sometimes, nitrogen can also be used for effective cooling to cool the temperature inside the furnace.

Vacuum aluminum brazing furnace. Quick Details

- Working Size: 400*400*500-1200*1200*1800mm

- Maximum temperature: 750℃

- Temperature uniformity: ±5℃

- Heating rate: 20℃/min

- Heating power: 80-160 kW

- Control accuracy: ±1℃

- Limit vacuum: 4.0*10-5

- Cooling rate: 30 750-280℃

- Pressure rise rate: 0.67 Pa/h

- Water cooling pressure: 6 bar M3/h

- Cooling water consumption: 30 M3/h

- Temperature control components: Japanese conductive

- Thermocouple type: K type

- Quantity of heating zones: 5 zone

- Heating element: NI20CR80

- Heating chamber shape: Cuboid

- Vacuum gauge type: Ionization compound vacuum gauge

- TouchScreen: Kunlun state (made in China)

- Nitrogen protection: Yes

Vacuum aluminum brazing furnace factory video

Vacuum aluminum brazing furnace advanced function

1. This device’s pressure and temperature data, including the vacuum pump’s speed, energy consumption, pressure, etc., are displayed digitally. The data are centrally displayed on the touch screen, allowing engineers to check them visually.

2. Engineers can program the working steps of vacuum brazing furnaces through touch screens to automate complex welding processes.

3. The furnace door adopts a side-opening design with a cylinder-driven flange locking that will not loosen at any time, ensuring good sealing performance.

4. To smoothly load and remove aluminum products into and out of the vacuum furnace, it has a dedicated forklift for loading goods, which is electric and does not require manual handling.

Installation precautions

For easier transportation, we will disassemble the vacuum furnace and reassemble it when it arrives at the customer’s factory. We need to consider a few details to assemble the vacuum furnace quickly.

- Factory space: Some vacuum furnaces have a large volume, so users need to purchase the most suitable size based on the factory space before booking the vacuum furnace to avoid installation difficulties.

- The factory must provide sufficient electricity, cooling water, and nitrogen for the aluminum vacuum brazing furnace to operate normally.

- We provide installation services but still require users to provide motorized forklifts and other necessary support.

- After the vacuum furnace’s installation, the first operation must undergo strict inspection. Each set of heaters must operate independently, and its temperature must be checked to ensure normal heating operation.

Summary of Vacuum brazing furnace

This vacuum furnace is an essential piece of industrial equipment. It can weld complex aluminum parts, such as fin heat exchangers, condensers, and other products.

It has a uniform water cooling device to provide a suitable working environment for the factory workshop and intelligent programmatic control to simplify complex control.

As experts in aluminum brazing technology, we can provide you with vacuum furnaces to meet your production needs and advanced technology to safeguard you, allowing you to obtain high-quality aluminum products without any worries.

If you are choosing an aluminum vacuum brazing furnace, choosing us is one of your best choices.

wechat

wechat