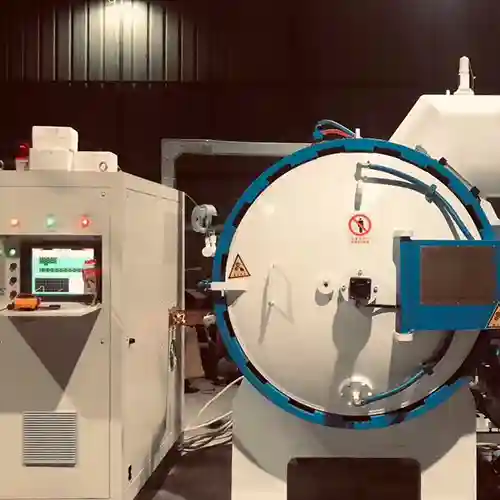

Product Description

A vacuum furnace is a high-temperature heat treatment equipment for metals in the industrial field. It mainly places metal materials in a vacuum environment, changes the properties of the metal through high temperature, and improves the durability and quality of the material.

Multiple temperature heating devices are put inside the furnace, and each area has independent thermocouples to collect temperature data. This multi-zone distribution independent control can ensure its temperature uniformity,

Some vacuum furnaces are using in special industries that require loading inert gases, such as gas quenching, aluminum brazing, etc. Inert gases can effectively ensure the stability of product quality and production efficiency.

With industry development, vacuum furnaces have been widely use in many fields.

Working principle

The basic principle of a vacuum oven is to place metal materials inside the oven chamber, and a vacuum pump will remove the air and impurities inside the stove, keeping the metal materials in a vacuum environment. During this process, the temperature will rise simultaneously,

When the temperature and vacuum pressure are optimal, maintain them for some time to allow the metal material to undergo plastic deformation and improve its quality.

Then, the cooling system will start working, quickly cooling the temperature inside the furnace and improving the efficiency of the vacuum furnace.

Application fields of vacuum furnace

- Metal material processing

The Vacuum furnace can be used for heat treatment of various metal materials, such as steel, alloys, tungsten, molybdenum, copper, aluminum, and other metals. It can achieve different heat treatment processes such as annealing, quenching, tempering, etc.

These processes can alter the chemical structure of metal materials, improve hardness and strength, toughness, and corrosion resistance

- semiconductor material

Vacuum furnaces also play an important role in the production of semiconductor materials. Heat treatment can eliminate impurities in semiconductor materials and improve material performance and stability.

- Ceramic industry

Due to the high-precision temperature uniformity of vacuum ovens and the application of inert gases, more and more factories in the high-end ceramic industry are using vacuum furnaces as the main production tool to ensure the quality stability of ceramic products.

- Aluminum brazing

An aluminum brazing furnace is an essential equipment in the production process of plate and bar heat exchangers. Due to its ability to freely control brazing temperature and time and the high quality of heat exchanger welds, no equipment can replace furnaces.

Vacuum Furnace Product List

Classification of Vacuum Furnaces

- High temperature and high vacuum pressure

Due to their high melting points, This vacuum furnace is used to heat treat special metals, such as stainless steel and titanium alloys. So, high temperatures and pressure must be used to achieve the best heat treatment effect.

- Low temperature and high pressure vacuum furnace

This vacuum furnace is using for heat treatment or brazing of aluminum and copper materials, which have low melting points and can meet their needs at a maximum temperature of only 650 ℃,

- High-temperature and low-pressure vacuum furnace

Some special industries have strict temperature requirements, but only low-pressure vacuum environments are needed, such as ceramic sintering, graphite annealing, etc. Therefore, this type of vacuum furnace has emerged,

Q & A

A: Our machine has a touch screen of 10 inches, available in both English and Chinese.

A: We can manufacture vacuum furnaces for welding aluminum materials.

A: We provide all technical support, machine installation, and technical training for free.

wechat

wechat