Product Description

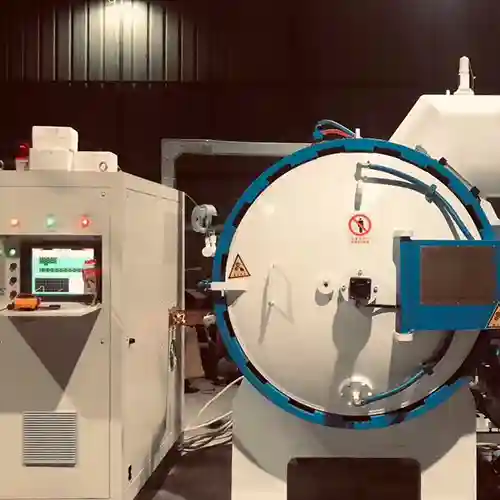

This vacuum gas quenching furnace is an important equipment for metal heat treatment. It controls the process flow of heat treatment through programming and can perform quenching, tempering, annealing, and other heat treatments on various metals,

PLC centralizes the control of this vacuum furnace, and engineers can program the heat treatment process through a 10-inch touch screen to set the best heat treatment solution for different metal parts,

Its furnace body is horizontally put with a side-opening door design, making transporting and transferring parts easier. A water-cooled tube is installed in the middle of the furnace body, which is a completely sealed structure. When the vacuum furnace needs to cool down, the valve of the water-cooled tube will automatically open to achieve rapid cooling, thereby improving work efficiency.

Vacuum Gas Quenching Furnace Technological Process

1. It takes about 50 minutes to heat at room temperature to 500 ℃, with a vacuum pressure of 6.7 * 10-1

When temperature and vacuum pressure reach the set values, the control system will start the next stage automatically.

2. Heating the vacuum furnace temperature from 500 ℃ to 800 ℃ for approximately 30 minutes, with a vacuum pressure of 6.7 * 10-2.

When temperature and vacuum pressure reach the set values, the control system will start the next stage automatically.

3. It takes about 30 minutes for the temperature of the gas quenching vacuum furnace to heat from 800 ℃ to 1000 ℃, with a vacuum pressure of 6.7 * 10-3.

When the temperature and vacuum pressure reach the set values, the vacuum quenching furnace will hold at 1000 ℃ for 45 minutes, allowing the metal material to receive sufficient heat.

(Different metal materials may have different temperatures)

4. Inject nitrogen into the vacuum furnace chamber, activate the water cooling system, and the furnace temperature will drop to 50 ℃ within 60 minutes.

5. Heat up to 180 ℃ within 30 minutes and maintain this temperature for 30 minutes. Temper the metal parts and then lower the temperature to room temperature,

6. Close the nitrogen and water cooling valves, open the furnace door to remove the metal parts from the vacuum furnace, and the entire quenching process ends here.

Vacuum Gas Quenching Furnace Technical Parameters

| ITEM | DATA |

| Vacuum pressure | 6.7*10-4pa |

| Control mode | fully automatic |

| Gas | Nitrogen |

| Temperature uniformity | ± 5 ℃ |

| Heating rate | 20℃/min |

| Maximum temperature | 1300℃ |

| Heating element | graphite |

| Temperature acquisition | thermocouple |

| Languages | English Chinese Russian Spanish |

Furnace Structure

The horizontal structure design of this vacuum gas quenching furnace single chamber consists of a horizontal cylindrical body with multiple different metals from inside to outside, such as graphite heating elements, 5-layer stainless steel sheets, furnace chambers, water cooling tubes, nitrogen pipelines, etc.

The front end is connected to the furnace mouth flange, and there is a flange interface left at the rear end of the furnace body, which is connected to the air-cooled motor. The bottom of the furnace is designed with a bracket to facilitate the placement of the furnace. The side is the interface of the vacuum pump.

The furnace door is pushed laterally by a cylinder to open. When the furnace door is close, the flange can rotate to lock the furnace door, which is a safe design to prevent the nitrogen-filled furnace door from popping open under vacuum.

Vacuum Gas Quenching Furnace factory video

Application of Metal Materials

- Nonalloy electrical steel

- Soft magnetic alloy steel

- Corrosion-resistant steel

- Heat-resistant steel

- high-speed steel

- Spring steel

- Nickel metal

- stainless steel

- Ordinary carbon steel

- Die steel

- Profile steel

- Other non-ferrous metal materials

Vacuum gas quenching furnaces have advanced functions

- Engineers can customize the heat treatment process to achieve different techniques such as quenching and annealing, Tempering, hardening, etc., and the heat treatment methods of these different processes are fully automated

- Multi-regional distributed temperature management achieves precise temperature control, with multiple layers of stainless steel plates isolating temperature diffusion outward. This not only saves energy consumption but also maintains a comfortable working environment in the factory workshop

- The vacuum quenching furnace comes with vacuum pumps from a well-known Chinese brand. Each vacuum pump provides strong vacuum pressure output and has a durable lifespan.

wechat

wechat