Product Description

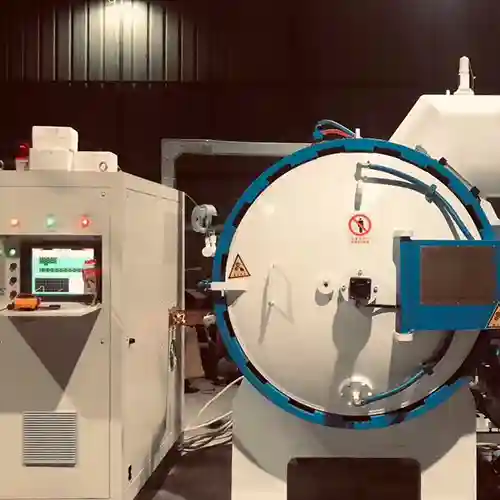

The Vacuum heat treatment furnace is an industrial equipment that uses molybdenum metal heating to heat treat metals in a vacuum environment. Compared with traditional heat treatment processes, vacuum furnaces can avoid metal materials’ oxidation and adverse chemical reactions.

The furnace for vacuum heat treatment comprises various devices with different functions, such as a vacuum pump, furnace body, water cooling, heating device, shovel, transformer, control device, etc.

The temperature of vacuum furnaces for different heat treatment processes may vary. Aluminum brazing only requires a maximum temperature of 750 ℃, while metal quenching requires 1350 ℃.

Technical Data

| ITEM | DATA |

| Power supply | 380v/50Hz customizable |

| Max temperature | 650-2000 ℃ |

| Working size | customized |

| Vacuum pressure | customized |

| Delivery time | 60-120 days |

| Cooling | Water cooling |

| Nitrogen protection | optional |

| Vacuum pump | Chinese brand |

Vacuum heat treatment furnace features

1. Automated temperature control

The temperature distribution in multiple zones of the vacuum furnace is uniformly distributed on all six sides of the chamber. The heating device is equipped with thermocouples to collect temperature data, and the PID control algorithm controls the temperature accurately.

2. Rapid cooling device

Each vacuum heat treatment furnace will be equipped with a pipe in the middle of the shell, and tap water will cool the vacuum furnace quickly, achieving higher work efficiency.

3. Intelligent control system

With industry development, the control of vacuum furnaces is becoming increasingly intelligent. Users can write control programs according to production process requirements to achieve fully automatic operation mode

Vacuum heat treatment furnace application

- Aluminum brazing:

The function of this vacuum furnace is to weld multiple complex aluminum parts together. Its maximum temperature is 750 ℃, and the temperature during normal use is about 610-620 ℃. The vacuum pressure needs to reach 10-5 ℃.

- Annealing:

This type of annealing vacuum furnace is used to relieve the stress on metals and improve the ductility of materials. Many types of vacuum furnaces can be used for annealing processes.

- Tempering:

After high-temperature quenching, metal parts must be kept in a vacuum furnace to allow sufficient time for the metal to undergo chemical changes.

- Sinter:

Multiple metal materials are sintered in a vacuum environment according to scientific proportions, and they dissolve with each other to form unique materials.

- Stainless steel brazing:

Stainless steel welding is different from aluminum. Stainless steel requires a higher temperature, usually 1350 ℃. Welding stainless steel parts in a vacuum environment can preserve the original luster on the surface of the parts.

Vacuum heat treatment furnace factory video

Classification of Vacuum Heat Treatment Furnaces

- Vacuum solid solution furnace

- Vacuum aging furnace

- Vacuum chemical heat treatment

- Vacuum coating furnace

- Vacuum Annealing Furnace

- Vacuum quenching furnace

- Vacuum tempering furnace

- vacuum carburizing furnace

- vacuum braze furnace

- Vacuum sintering furnace

WHY CHOOSE US

1. We are a top manufacturer from China with advanced manufacturing technology, producing various vacuum furnaces with different functions.

2. Experienced team in the field of vacuum heat treatment furnaces, providing professional after-sales service and technical support for users

3. Our factory is located in China’s most developed industrial city, where industrial manufacturing offers globally competitive prices.

4. The most advanced control technology for precise temperature control systems is installed for each vacuum furnace, which can be remotely assisted and updated.

Q & A

A: Of course, please get in touch with our engineers to easily access our catalog.

A: The maximum temperature of an aluminum brazing furnace is usually 750℃ Celsius; the actual usage is approximately 630℃.

A: We can accept size customization; you can contact us for more details.

A: We can design a control system to meet your power supply needs.

wechat

wechat