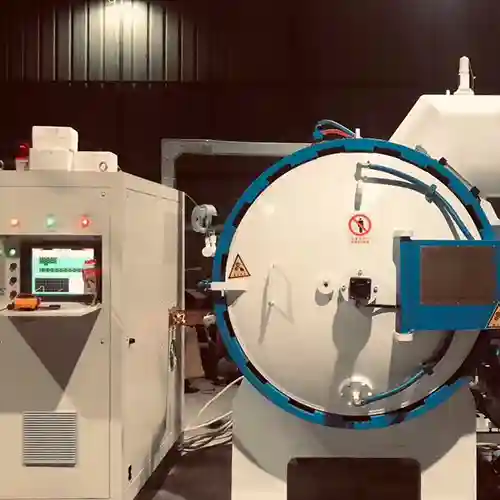

Machine Overview

Universities or research companies mainly use this small vacuum induction furnace to experiment with metal materials and melt them under vacuum conditions.

This device adopts induction heating technology and can also be used for vacuum refining and precision casting rare metals.

This device uses temperature control instruments to control power heating, and temperature measurement uses platinum-rhodium thermocouples for more accurate temperature control.

The working chamber is made of stainless steel material, and a water cooling device is installed in the middle of the furnace body to maintain the stable operation and rapid cooling ability of the equipment

Vacuum induction furnace quick details

| No. | ITEM | DATA |

| 1 | Voltage | 380V 50Hz 3-phase |

| 2 | Chamber material | 304 stainless steel |

| 3 | Vacuum chamber size | 1000mm×1400mm |

| 4 | Crucible volume | 120×150mm |

| 5 | Melting capacity | 5-20KG |

| 6 | Common temperature | 3000 °C |

| 7 | Working atmosphere | vacuum or Ar N2 gas protection |

| 8 | Temperature control | PID intelligent program |

| 9 | emperature control accuracy | +-1% |

| 10 | Protection method | PLC intelligent warning alarm protection |

Vacuum induction furnace characteristic

- Adopting induction heating, the maximum temperature can reach 2100 ℃

- The touch screen can set the vacuum pressure and temperature according to your process requirements, automatically heating or cooling according to the process

- The vacuum furnace has a pouring device that can pour the melted metal liquid into the container

- It can melt under various conditions, such as a vacuum state and atmosphere protection state

- Optional secondary feeding device, adding other elements during the melting process to produce diversified metal samples

- There is a water cooling device, and the temperature of the outer shell is below 35 ℃ during operation

wechat

wechat