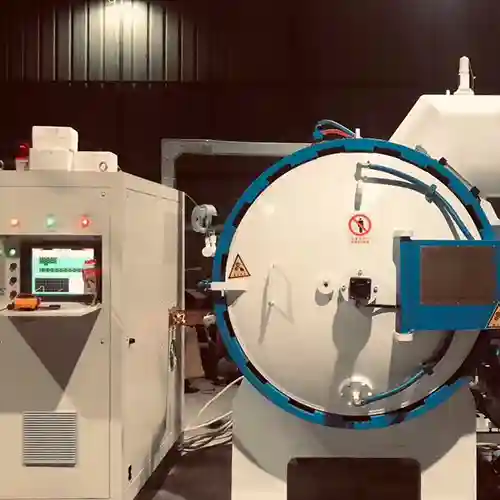

Machine Overview

The Vacuum sintering furnace is a device that utilizes the principle of medium-frequency induction heating and operates under the protection of hydrogen gas after vacuuming.

It heats the tungsten crucible to high temperature through an induction coil and then conducts heat radiation to the workpiece for sintering.

This type of furnace is suitable for powder forming and sintering of refractory alloys such as tungsten, molybdenum, and their alloys in scientific research and military industry units.

vacuum sintering furnace characteristics

1, Medium frequency induction heating: Medium frequency induction heating has the characteristics of high efficiency and fast heating,

which can heat the tungsten crucible to the desired high temperature in a short time.

2, Vacuum and hydrogen protection: When the equipment operates in a vacuum environment,

it can effectively remove oxygen and other harmful gases, reducing the impact of impurities on the sintering process.

By filling with hydrogen gas for protection, it is possible to prevent material oxidation, control the atmosphere, and prevent oxidation reactions of the material powder.

3, Wide application range: A vacuum sintering furnace is mainly used for powder forming and sintering of refractory alloys such as tungsten, molybdenum, and their alloys.

These materials are difficult to melt under conventional process conditions and require high temperatures and special atmosphere conditions.

4, Research and military applications: Due to its ability to provide precise temperature control and a high-temperature environment,

vacuum sintering furnaces are widely used in scientific research and military fields.

Researchers and military units can use this equipment to shape and study complex materials to meet specific needs.

Vacuum sintering furnace echnical details

| No. | ITEM | DATA |

| 1 | Maximum temperature | 2500℃ |

| 2 | Cooling type | water-cooled |

| 3 | Furnace cavity size | customized |

| 4 | Delivery time | 120 days |

| 5 | Control | Programmable fully automatic |

| 6 | Door lock | cylinder |

| 7 | Gas protection | hydrogen gas |

vacuum sintering furnace manufacture video

FAQ

A: Contact our engineer, he will send you the catalog.

A: We accept customization of any size.

A: Installation and training will take approximately 30-45 days.

wechat

wechat