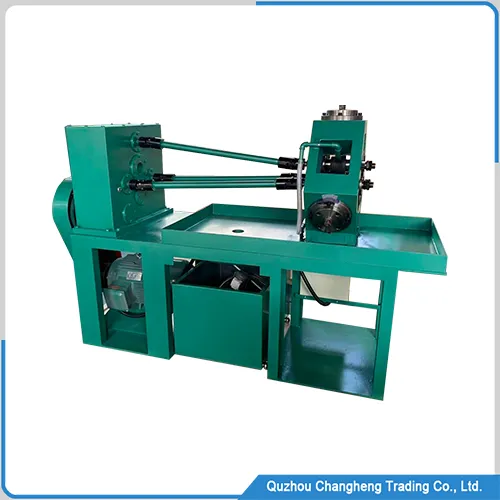

Product Description

This vertical expander machine is a key equipment for producing household air conditioning condensers. It expands the diameter of copper pipes vertically, allowing the cooling fins and copper pipes to be tightly combined.

Usually, the primary power source of machines is hydraulic drive. With the development of technology and industrial progress, modern vertical tube expansion machines are driven by servo motors, which not only have no noise from hydraulic stations but also save a lot of electricity.

Vertical expander machine characteristic

- Complete multiple tasks with a single workflow.

This device can achieve multiple steps in one workflow, including compressing the head plate and aluminum fins, expanding all pipes at once, and further expanding the edges of the pipes.

- Accurate control of expansion length

This machine’s maximum length is 2800 mm, and users can produce condensers of any length size less than 2800 mm. Thanks to the reliability of the servo motor, this machine can accurately control the length of expansion.

- Reliable parts

The device’s expansion rod and ball have undergone vacuum quenching heat treatment, significantly improving their hardness and wear resistance and extending their service life.

- Silent production

Compared to the hydraulic station-driven machines of old technology, this vertical expander machine hardly makes any sound.

- Advanced control

We have rearranged the complex and messy control buttons, concentrating them on a 10-inch touchscreen that allows users to control the device intuitively, significantly reducing learning costs.

Vertical expander machine technical data

| ITEM | DATA |

| Expansion method | Vertical |

| Door opening method | Manual |

| Pipeline diameter | 6-20mm optional |

| Drive type | Hydraulic station Servo motor optional |

| Pipe layout | Follow the design |

| Drive Type | Spring steel |

| Control type | Centralized control |

| Application | Condenser Heat Exchanger |

Vertical expander machine working video

Optional configuration

Users can choose between machines driven by hydraulic stations or servo motors, and there are some price differences between the two

A Vertical expander machine can choose one way to open the door, usually including rotation, manual opening, and flipping for users to choose from,

U-shaped pipes may or may not contract during the expansion process, and their prices also vary slightly.

Copper pipes’ geometric layout is customized according to user requirements. You can also choose whether the edges of the pipes have expansion ports.

Other condenser machines

Condenser fin mold and Progressive die

Product Introduction The condenser fin mold is a tool for continuous high-speed production. It is a fully auto progressive mold tool that combines multiple molds with different functions. This mold is the main production tool…

Fin production line of Heat exchanger | fin punching line

Production line overview The High-speed Heat exchanger fin production line is a special cast iron alloy with high rigidity and shock resistance. The slider is designed with a long guide circuit and equipped with a…

Tube expanding machine for Industrial heat exchanger

Product Description The Tube expanding machine is the latest equipment driven by servo motors. The motor-driven gear increases the power output by 10 times, and this powerful force can easily expand any metal pipe. Whether…

Q & A

A: Usually, it is an expandable U-shaped tube compatible with straight tubes.

A: Replace the machine driven by a servo motor, which is energy-saving and noise-free.

A: You need to share the fin design or hole layout before we start manufacturing this machine

wechat

wechat