Fin machine outline

Stamping-type fin machines usually produce iron, stainless steel, aluminum, copper, titanium alloy, etc.

The thickness of raw materials is about 0.03-0.5mm, and the maximum width is 450mm. Some custom machines can produce larger widths.

There are several different types of fin machines: Stamping type, Roller type, and continuous mold production types,

| ITEM | DATA |

| raw material | produces iron stainless steel aluminum copper titanium alloy |

| Raw material thickness | 0.03-0.5mm |

| Hole type | circular elliptical |

| Production type: | continuous production |

| Control | PLC |

| Touch screen brand | Chinese brand |

These fin machines are widely used in ships, automobiles, aerospace, industrial cooling, oil, and other industries

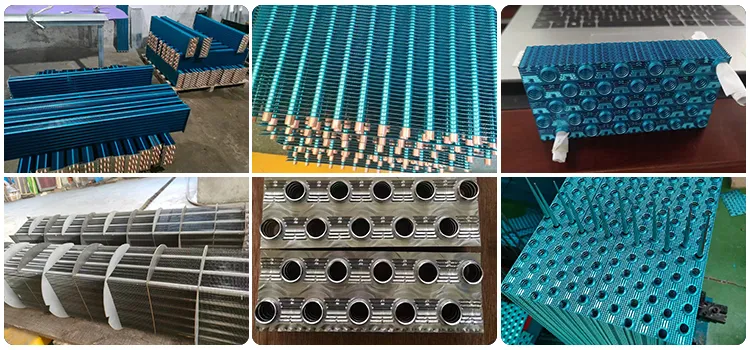

Roller-type fin machine mainly produce aluminum and copper materials, It is usually used to produce automobile parts, condensers, radiators, evaporators, intercoolers, etc. Because of its fast production speed, it is a widely used

continuous mold production machine; it mainly produces air-conditioning condensers, industrial heat exchangers, and large coolers; its application fields are also very many

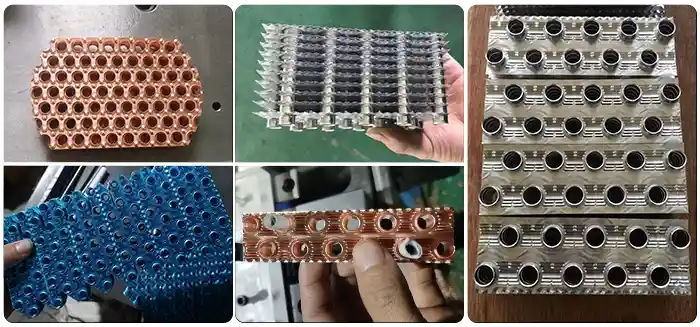

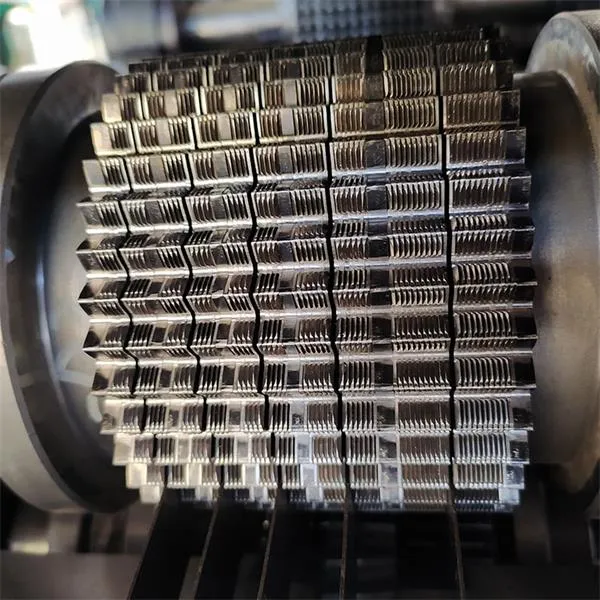

Stamping type characteristic

The maximum width of this machine is 300mm or 450mm. It can produce multiple small-sized fins simultaneously,

with a production speed of 144 times per minute; different fins can be manufactured by changing the mold. Changing tools can produce fins of different height sizes, For example, serrations, waves, straight lines, louvers, etc.,

This is a necessary machine for some factories manufacturing heat exchangers and oil coolers

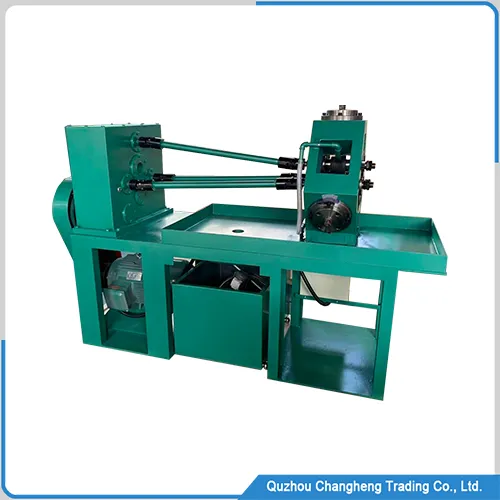

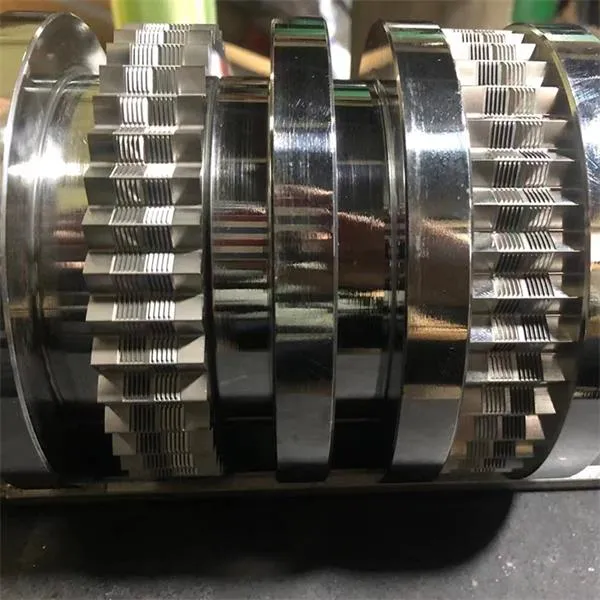

Roller-type fin machine characteristic

Its production speed is very fast, producing 120 meters of raw materials per minute.

The production quality is very stable. The roller and the machine are designed separately, and the roller can be replaced independently. There is no error in the length of the fin produced by setting the parameters of the machine,

| ITEM | DATA |

| Color | Customized |

| Total voltage | 2.5kw |

| Power supply | 3-phase/380v |

| Roller material | W6Mo5Cr4V2 |

| Cut off | Servo motor |

| Maximum width | 16-120mm |

| Servo motor brand | Delta |

| Fin material | Aluminum, copper |

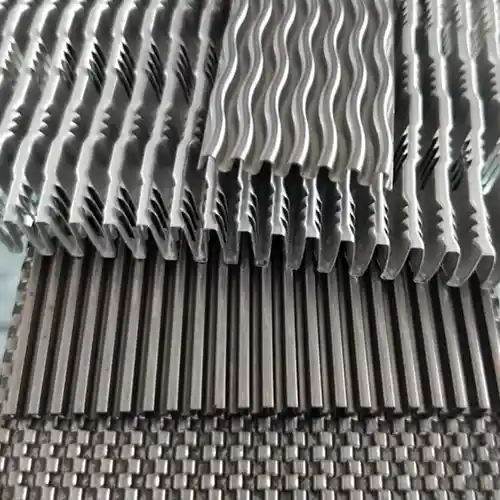

Continuous mold production machine characteristic

A high-speed Heat exchanger fin punching machine is made of a special cast iron alloy with high rigidity and shock resistance. The slider is designed with a long guide circuit and equipped with a slider balance device to ensure precision and stability of operation.

Continuous mold production Fin machine

All anti-wear components are equipped with an electronic timing automatic lubrication system. If there is a lack of lubricating oil, the press will stop automatically. An advanced and simple control system ensures the slider’s running and stopping accuracy. It can match any automatic production demand, improve efficiency, and reduce costs.

A high-speed Heat exchanger fin punching line is widely used in small precision parts such as precision electronics, communication, computers, household appliances, auto parts, Mada stators, and rotors.

wechat

wechat